Stained Glass Products

Stained Glass Products - A Timeless Art for Homes

Stained glass has always been an exquisite form of art that has been admired for the way it brings the light to life. The use of stained glass decorates even the most common items and adds some elegance to them while also serving their regular purpose.

Many women entrepreneurs make amazing stained-glass products that are highly appreciated for the aesthetic and colorful yet useful art that these products bring to any home.

Stained Glass Table Lamps

Stained Glass Table LampsThe Legacy of Stained Glass

Stained glass is more than just a decorative feature; it’s a storytelling medium that has been cherished across cultures and eras. By incorporating stained glass into our homes, we are connecting with a rich artistic tradition while adding a unique, personalized touch to our living space.

Stained glass, a form of art that uses colored glass to create intricate designs, has its origins deeply rooted in history, blending artistic expression with architectural innovation. Its journey spans centuries, reflecting cultural and religious influences across the world

- Ancient Roots: The origins of stained glass can be traced back to ancient Egypt and Mesopotamia (circa 2000 BCE), where craftsmen used colored glass for jewelry, vessels, and small decorative items. Techniques for adding metallic oxides to molten glass, which produced vibrant colors, laid the groundwork for later stained-glass artistry.

- Roman Influence: The Romans expanded the use of colored glass in mosaics and windows during the 1st century CE, often in public baths and temples.

- Rise in Churches: Stained glass reached its zenith in medieval Europe (10th–16th centuries), adorning the windows of Gothic cathedrals. Iconic examples include the windows of Chartres Cathedral in France and Canterbury Cathedral in England. These windows served both decorative and didactic purposes, illustrating biblical stories for largely illiterate congregations.

- Techniques: Craftsmen used lead cames to join pieces of colored glass, painting details with powdered pigments fired onto the glass. The vivid colors were achieved using metallic oxides: cobalt for blue, gold for red, and copper for green.

- Shift in Focus: During the Renaissance, interest shifted toward painted glass, and the grandeur of stained glass waned as architectural styles moved away from large, ornate windows. Many medieval stained-glass windows were destroyed during the Reformation and other periods of iconoclasm.

- Gothic Revival: The 19th century saw a renewed interest in stained glass, driven by the Gothic Revival movement. Artists like William Morris and companies such as Tiffany & Co. elevated the craft, blending medieval techniques with modern aesthetics.

- Homes and Public Installations: Stained glass expanded beyond religious buildings to secular settings, such as homes, offices, and public art installations.

- Contemporary Designs: Artists experiment with abstract designs, new materials, and innovative techniques, keeping the tradition alive.

The art of stained glass reflects humanity’s enduring fascination with light, color, and storytelling. From ancient temples to modern architecture, it continues to inspire awe and connect us to history.

Applications of Stained Glass in the Home

Stained Glass Shades for Table Lamps

Stained glass lamp shades are a classic way to incorporate this art form into your home.

- Design: Crafted with colorful glass pieces arranged in intricate patterns, they create a warm, diffused light.

- Styles: From floral motifs to geometric patterns, lamp shades suit a range of interior styles.

- Placement: Ideal for living rooms, bedrooms, or as statement pieces in reading corners.

Stained Glass Table Lamp

Stained Glass Table Lamp Stained Glass Table Lamps

Stained Glass Table Lamps Stained Glass Table Lamps

Stained Glass Table LampsStained Glass for Mirror Frames

Mirrors framed with stained glass combine utility with decoration.

- Aesthetic: The glass frame adds depth and color, elevating a simple mirror into an eye-catching piece.

- Uses: Common in bathrooms, hallways, or as accent decor.

- Design Options: Frames can be customized with colors and patterns to match the space.

Stained Glass Mirror

Stained Glass Mirror Stained Glass Mirror

Stained Glass Mirror Stained Glass Mirror

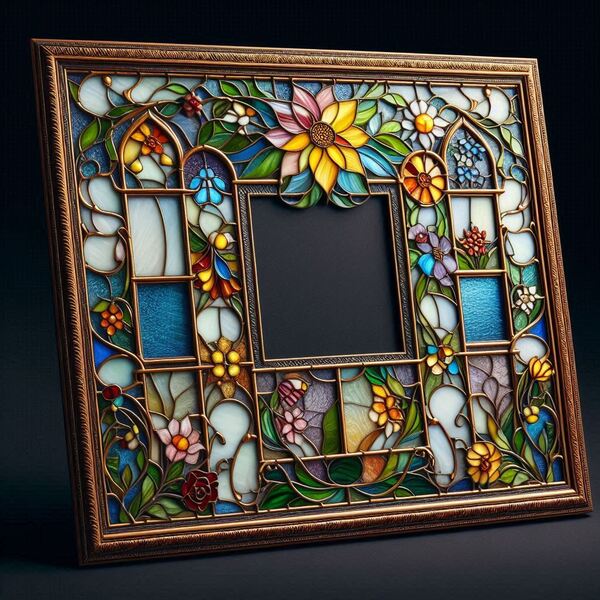

Stained Glass MirrorStained Glass for Picture Frames

Stained glass picture frames are perfect for highlighting treasured memories.

- Design Details: These frames often feature bold colors and intricate designs, making them small works of art.

- Versatility: Suitable for various photo sizes, from small desk frames to larger wall-mounted options.

- Decorative Value: Frames can complement the colors and themes in the photographs, enhancing their presentation.

Stained Glass Picture Frame

Stained Glass Picture Frame Stained Glass Picture Frame

Stained Glass Picture Frame Stained Glass Picture Frame

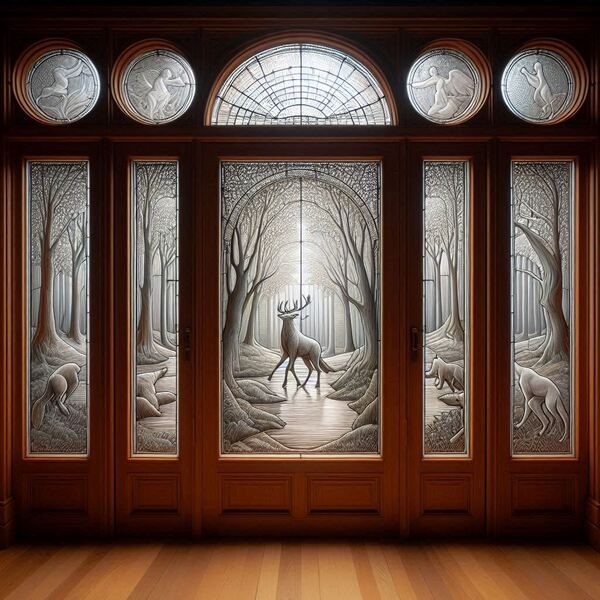

Stained Glass Picture FrameStained Glass Main Doors

Stained glass doors serve as a grand entrance to any home.

- Design Choices: Options range from fully stained-glass panels to smaller inserts within wooden or metal doors.

- Functionality: While decorative, stained glass also ensures privacy without sacrificing natural light.

- Customization: Common designs include floral patterns, abstract shapes, and traditional motifs.

Stained Glass Door

Stained Glass Door Stained Glass Door

Stained Glass Door Stained Glass Door

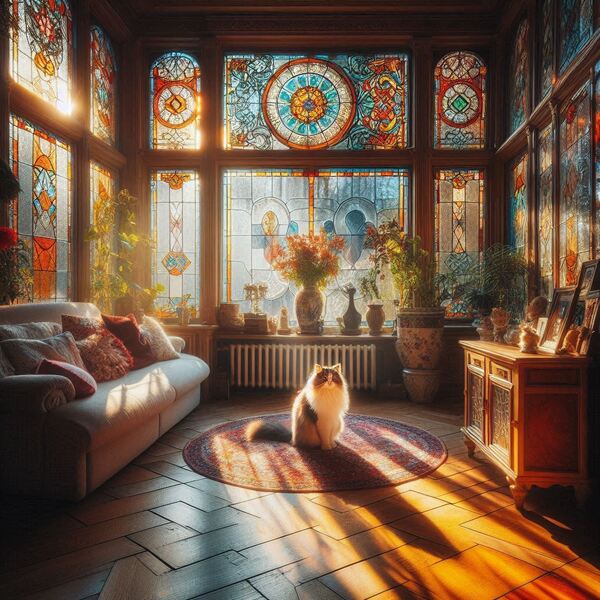

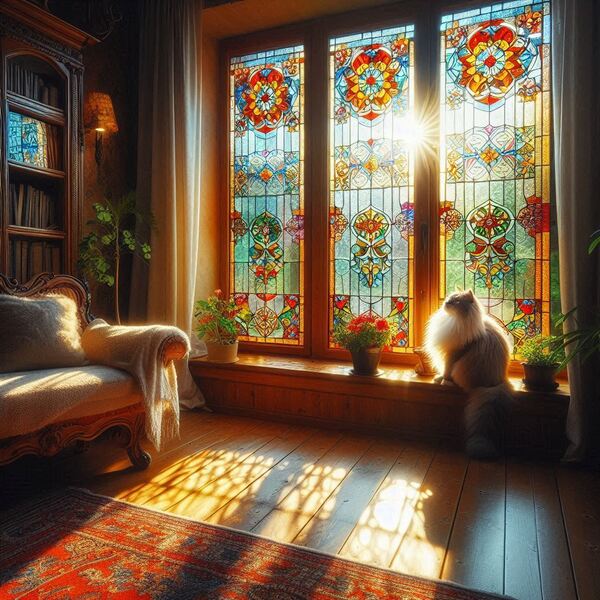

Stained Glass DoorStained Glass for Windows

Stained glass windows are perhaps the most iconic use of this medium.

- Visual Impact: These windows allow sunlight to filter through colored glass, casting vibrant patterns into the room.

- Common Locations: Found in kitchens, bathrooms, entryways, or as standalone decorative features.

- Practicality: They provide privacy while maintaining a connection to natural light.

Stained Glass Window

Stained Glass Window Stained Glass Window

Stained Glass Window Stained Glass Window

Stained Glass WindowStained Glass Products - Benefits of Stained Glass in Household Items

- Aesthetic Enhancement: Adds an artistic element that elevates the appearance of any space.

- Durability: Stained glass is long-lasting and retains its vivid colors over time.

- Play of Light: Creates dynamic visual effects as natural or artificial light interacts with the glass.

- Versatility: Complements a variety of architectural styles, from traditional to modern.

Stained Glass Products - Caring for Stained Glass

To maintain the beauty of stained glass, occasional cleaning with a soft, damp cloth is sufficient. Avoid abrasive cleaners to protect the finish and ensure the longevity of the artwork.

Stained Glass Products - The Crafting Process

How Stained Glass is Made: The Art and Craft Behind the Beauty

Creating stained glass items involves a blend of artistic vision and meticulous craftsmanship. The process has been refined over centuries, yet it still follows traditional techniques that require skill, patience, and creativity. Here’s an overview of how stained glass is made:

1. Designing the Pattern

The process begins with a design, often referred to as a "cartoon."

- Conceptualization: Artists draw a full-scale sketch of the design, outlining the shapes and colors of each glass piece.

- Planning: The cartoon serves as a blueprint, with each section representing a specific piece of colored glass.

2. Selecting the Glass

Stained glass comes in a variety of colors, textures, and transparencies.

Types of Glass: Options include opalescent (translucent) glass, antique glass (hand-blown), or textured glass.

Coloring: Glass colors are achieved by adding metal oxides to molten glass. For instance:

- Cobalt oxide creates blue.

- Copper produces green.

- Gold results in red hues.

3. Cutting the Glass

Each piece of the design is cut from sheets of stained glass.

- Tools: Glass cutters or specialized tools score the glass along the desired lines.

- Precision: Craftspeople use the cartoon as a guide, ensuring each piece fits perfectly into the overall design.

4. Shaping the Pieces

Shaping ensures the edges of each piece are smooth and precise.

- Grinding: A glass grinder smooths the edges, allowing for a snug fit during assembly.

- Adjustments: Pieces may be fine-tuned to match the design exactly.

5. Leading or Foiling

The glass pieces are joined together using one of two methods:

- Lead Came: Strips of lead (called cames) hold the glass pieces together.

The lead is shaped into channels, and the glass pieces are slotted inside.

- Copper Foil: Thin strips of adhesive copper foil are wrapped around each piece of glass.

This method allows for more intricate designs and finer details.

6. Soldering

The joined pieces are secured with solder (a metal alloy).

- Process: A soldering iron melts the solder, which bonds the lead or copper foil pieces together.

- Reinforcement: This step ensures the panel is sturdy and durable.

7. Applying Patina (Optional)

Patina is used to change the color of the solder lines.

- Types: Black or copper patinas are common, depending on the desired aesthetic.

- Effect: It adds contrast and enhances the overall appearance of the piece.

8. Cleaning and Polishing

The final step involves cleaning the stained glass.

- Removal of Residue: Flux residue (from soldering) is cleaned off to prevent corrosion.

- Polishing: The glass is polished to bring out its colors and shine.

Modern Innovations

While the traditional methods remain popular, modern techniques and tools have added efficiency:

- Laser Cutting: For precise glass shapes.

- Kiln Firing: Fuses designs onto the glass surface for painted details.

- Epoxy or Silicone Bonding: Provides alternatives to lead or copper in certain applications.

The End Result

The finished stained-glass piece is a harmonious blend of vibrant colors and intricate craftsmanship, ready to transform light and space into something extraordinary. Whether for windows, doors, or decorative objects, each piece is a testament to the skill and artistry of its maker.

Harmful Chemicals Used in Making Stained Glass

The process of creating stained glass involves certain materials and chemicals that can pose health and environmental risks if not handled properly. Below is an overview of the potentially harmful substances used in the craft and their associated risks.

1. Metal Oxides for Coloring Glass

- Chemicals Used:

- Cobalt Oxide: Used for blue glass.

- Copper Oxide: Creates green hues.

- Selenium or Cadmium Compounds: Produces red and orange colors.

- Lead Oxide: Found in some antique or traditional glass recipes to achieve clarity and brilliance.

Risks:

- Can cause skin irritation or respiratory problems if inhaled as fine dust.

- Some oxides (like cadmium and lead) are toxic and potentially carcinogenic with prolonged exposure.

2. Lead in Lead Came

- Source: Lead strips (cames) used to join pieces of glass together.

Risks:

- Prolonged exposure to lead can lead to lead poisoning, which affects the nervous system and kidneys.

- Inhalation of lead fumes during soldering or handling without gloves increases risk.

3. Solder and Flux

- Materials Used:

- Solder: Typically an alloy of tin and lead.

- Flux: Chemicals used to clean and prepare metal surfaces for soldering, often containing ammonium chloride or zinc chloride.

Risks:

- Flux can emit harmful fumes during soldering, irritating the eyes, skin, and respiratory system.

- Lead solder poses additional risks, especially if heated in poorly ventilated spaces.

4. Patina Solutions

- Chemicals Used:

- Copper Sulfate: For copper-colored patina.

- Selenium Dioxide: Used for black patina.

Risks:

- Patinas are corrosive and can cause chemical burns on contact with skin or eyes.

- Fumes during application may irritate the respiratory system.

5. Glass Dust and Silica

- Source: Generated during cutting and grinding glass.

Risks:

- Inhaling fine silica particles can cause silicosis, a lung disease.

- Long-term exposure increases the risk of lung cancer.

6. Paints and Enamels

- Materials Used:

- Some paints and enamels contain heavy metals like lead, cadmium, or chromium to achieve vibrant, durable colors.

Risks:

- Handling or firing these paints in a kiln can release harmful vapors.

- Direct contact with skin can lead to chemical absorption and toxicity.

By understanding and mitigating these risks, artists can safely practice the craft of stained glass while protecting their health and the environment.

Stained Glass Products - Safety Measures in Stained Glass Making

- Ventilation: Work in a well-ventilated area to avoid inhaling fumes and dust.

- Protective Gear: Wear gloves, goggles, and a mask (preferably an N95 respirator) when handling chemicals or grinding glass.

- Proper Storage: Store chemicals in labeled, sealed containers away from children and pets.

- Regular Cleanup: Clean workspaces frequently to minimize accumulation of glass dust or chemical residues.

- Avoid Skin Contact: Use tools to handle chemicals and wash hands thoroughly after working.

- Environmental Disposal: Dispose of hazardous materials (like used flux, lead scraps, or patina waste) according to local environmental regulations.

- Home ›

- Products and Trades ›

- Stained Glass Products